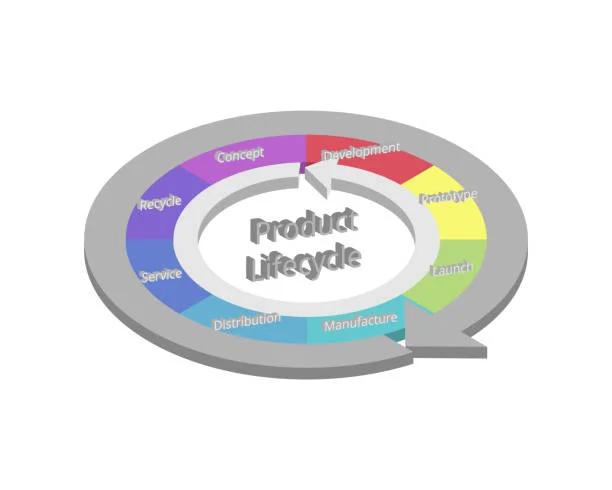

Reliable materials influence the strength, stability, and long-range performance of every commercial project, and they shape outcomes far more than many teams expect during early planning. Strong material choices support design clarity, smoother construction, predictable maintenance, and controlled costs throughout the building’s life. When owners and project teams take time to review quality, testing data, and supplier reliability, they protect the value of the structure from the earliest design decision to the final upgrade many years later. This article explains how reliable material selection influences each stage of a project lifecycle and why material decisions deserve greater attention during planning and execution.

Discover insights that matter—dive into our Related Posts and stay ahead today!

Why materials shape the lifecycle of every project

Materials influence every layer of a build, including design, construction, daily use, long-term maintenance, and final replacement planning. Each stage relies on materials with consistent performance, stable form, and predictable behavior under real conditions. Strong materials support clear planning and streamlined installation, while weak materials introduce delays, safety issues, and higher long-term costs. The difference becomes clear when project teams track outcomes over several years. Reliable suppliers play an important role, which is why many facility managers use stable solutions from One Point Partitions for projects where performance and durability matter.

Material strength influences engineering calculations, interior layout, safety planning, and risk control. Every team involved in the project relies on those choices, so decisions made during early planning shape everything from installation speed to operational stability. Once weak materials enter a build, the negative effects remain in place for years, so the choice during early planning has long-range influence over the entire lifecycle.

Early planning and specification advantages

Reliable materials make early planning more precise, since strong manufacturers provide detailed testing data, verified performance metrics, and clear installation guidelines. Architects benefit from this information because structural expectations become easy to define. Engineers work with materials that hold their form and respond in stable ways, which reduces uncertainty during design. Contractors bid on specifications with accurate expectations about installation time, labor needs, and tooling requirements, so early clarity sets the project on a stable path.

Material quality also influences permitting. Teams working through the construction permitting process often encounter fewer delays when materials align with regulatory expectations. Performance data, fire-resistance information, and compliance documents simplify reviews and reduce the risk of revision requests. Every hour saved during permitting improves scheduling accuracy and reduces pressure on downstream tasks, which helps project teams maintain momentum from start through completion.

Smooth construction and installation outcomes

Construction schedules depend on reliable materials. When materials arrive with consistent dimensions, stable finishes, and verified strength levels, crews spend less time fixing issues, correcting alignment problems, or addressing unexpected failures. Consistent quality supports predictable installation work, keeping the timeline stable and reducing stress on labor teams. Installation workflows move faster when crews know each piece will perform as expected under stress, moisture, or temperature shifts.

Using reliable materials is key to minimizing rework, which otherwise consumes labor hours, delays progress, and drives up overall project costs. When materials meet precise tolerances, the installation process adheres to the original plan, thereby avoiding disruptions.

Furthermore, construction outcomes are significantly influenced by a stable supply chain. Dependable suppliers maintain sufficient inventory, provide accurate lead times, and communicate changes promptly. This stability ensures a smooth installation sequence and reduces downtime caused by unforeseen shortages.

Performance during daily use

Daily performance determines whether users experience comfort, cleanliness, and stability throughout the building’s life. High-quality materials handle frequent use without bending, chipping, swelling, or losing structural integrity. Surfaces stay clean, fixtures hold their position, and structural components remain stable under pressure. This level of reliability supports predictable operation for building owners and facility managers and helps maintain a positive experience for employees, tenants, and visitors.

Durable materials limit wear patterns that appear quickly with weaker products. Scratches stay minimal, surfaces resist moisture intrusion, and structural movement becomes rare. Over time, this stability protects the appearance of the property and reduces the number of service calls needed to restore surfaces or adjust fixtures. Smooth daily performance becomes one of the clearest advantages of using reliable materials during construction.

Maintenance and long-term cost control

Using high-quality, durable materials significantly reduces long-term building expenses, primarily maintenance costs. These materials lower annual labor needs due to less frequent inspection, fewer repairs, and extended replacement cycles. This durability allows for predictable budgeting and minimizes unexpected failures.

Furthermore, reliable materials reduce building downtime and disruption, ensuring consistent operations and occupant satisfaction. Their extended lifecycle postpones major upgrades, benefiting both annual and long-range capital planning.

Risk reduction and compliance support

Material strength ties closely to safety and regulatory compliance. Surfaces, fixtures, and structural components must maintain shape and stability during heat, moisture, pressure, impact, and cleaning. Reliable materials help teams satisfy building code requirements and reduce the risk of inspection failures. When materials include documented fire ratings, chemical resistance data, load performance information, or moisture resistance results, inspectors work with accurate information, and approvals move faster.

Stable materials reduce hazards throughout the building. Failures involving loose panels, cracked surfaces, or compromised structural components create liability risks for property owners, and those risks grow when weak materials degrade early. Reliable materials hold form during daily use and emergency conditions, which protects users and reduces exposure to legal and operational issues.

Environmental and sustainability benefits

Sustainability goals benefit from durable materials because longer lifespans reduce waste produced by frequent replacement. Fewer discarded parts support environmental responsibility, and stronger materials help facilities maintain stable performance with lower waste generation over time. Some materials also support energy efficiency, since reliable insulation, quality cladding, and high performance finishes influence heat flow and energy demand inside the building.

Maintenance tasks also influence environmental outcomes. Durable surfaces require fewer chemicals, fewer repairs, and fewer replacement materials, which lowers the overall environmental footprint of the property. These advantages support organizational sustainability targets and align well with modern commercial facility expectations.

Choosing reliable suppliers and manufacturers

Supplier selection remains one of the most important steps in material planning. Reliable suppliers provide comprehensive testing data, performance records, and warranty support. They communicate clearly and maintain steady inventory, which reduces the risk of substitution during construction. Manufacturers with strong quality controls produce materials with consistent strength, form, and durability, which improves outcomes at every stage.

Project teams benefit from reviewing supplier history, certifications, and long range performance benchmarks. Strong suppliers answer technical questions, support installation teams, and help resolve unexpected issues before they cause delays. Long term relationships with dependable manufacturers improve building outcomes and support lifecycle stability over many years.

Conclusion

Reliable material selection strengthens every stage of a project lifecycle. Early planning becomes more precise, construction moves with greater stability, daily use remains predictable, maintenance costs stay controlled, and long term capital planning becomes easier to manage. Project teams who focus on quality materials and dependable suppliers protect their investment and improve safety, appearance, and operational stability throughout the building’s life.

Don’t miss out—our Featured Posts are packed with trends, tips, and stories!