Introduction to RepMold Technology

What Is RepMold?

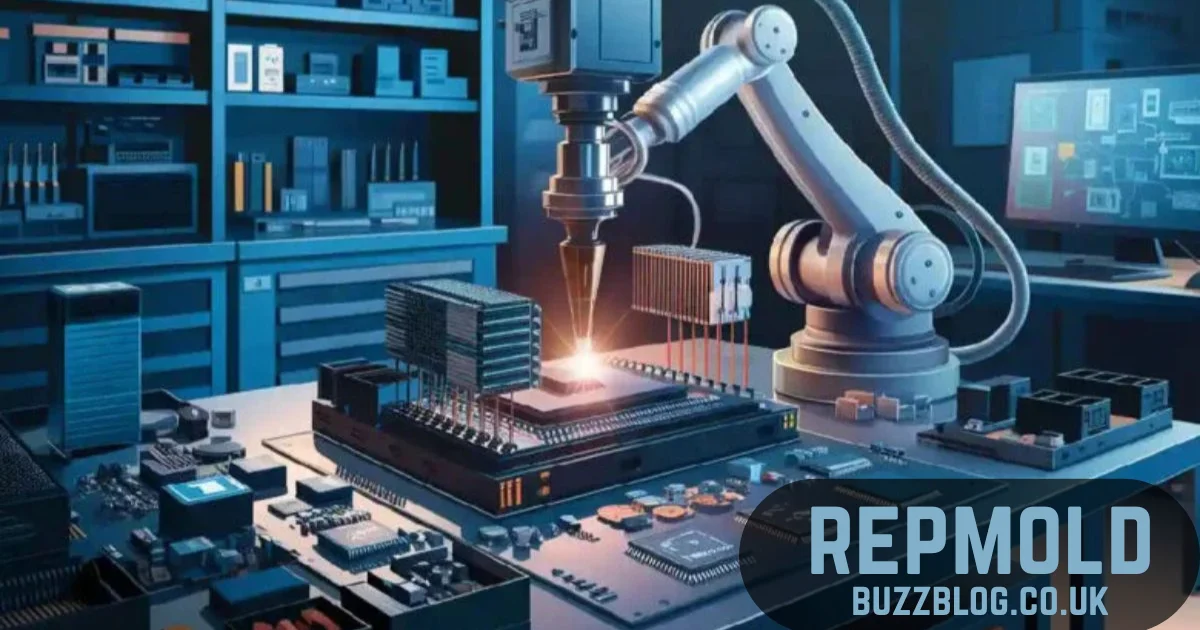

RepMold is an innovative mold production technology that has transformed how manufacturers design, produce, and refine molds across multiple industries. It delivers unmatched precision, rapid production, and remarkable flexibility—three pillars modern industries depend on to stay competitive. Think of it as the “smart machine” of mold manufacturing, capable of doing in hours what used to take weeks.

Why RepMold Matters in Modern Manufacturing

In an era where customers demand faster delivery, higher accuracy, and flawless quality, RepMold fills a crucial gap. Traditional mold-making often struggles to keep up with fast-paced production cycles and tighter tolerances. RepMold eliminates these barriers, allowing manufacturers to accelerate innovation without compromising quality.

The Evolution of Mold Production

Traditional Mold-Making Challenges

High Costs and Long Development Cycles

Conventional mold production typically involves heavy manual labor, multiple test iterations, and prolonged timelines. This not only increases costs but also slows down product development.

Limitations in Design Complexity

Traditional techniques often fail to create highly intricate or micro-detailed designs. The process is restricted by the limitations of manual machining and outdated tools.

The Shift Toward Automation and Smart Manufacturing

Over the past decade, industries have moved toward digital and automated production methods. RepMold sits at the forefront of this digital transformation, blending automation, AI, and precision engineering into one powerful system

Key Features of RepMold

Precision at Micron-Level

RepMold achieves a level of accuracy that was once considered impossible in mold-making. With micron-level precision, manufacturers can produce molds that fit perfectly with minimal need for adjustments.

Ultra-Fine Surface Finish Capabilities

Thanks to advanced finishing technologies, RepMold can create molds with smooth surfaces, reducing the need for post-processing and improving final product quality.

Rapid Production Speed

One of RepMold’s biggest breakthroughs is speed. What used to take days or weeks can now be achieved in hours.

Reduced Lead Times from Weeks to Hours

Manufacturers can move from concept to testing almost instantly, helping them shorten product launch timelines significantly.

Flexibility for Complex Designs

RepMold effortlessly handles complex geometries and intricate structures that would be nearly impossible to create using older methods.

Adaptability Across Industries

Whether it’s aerospace components, medical tools, or consumer gadgets, RepMold adapts seamlessly to different material and design requirements.

How RepMold Works

Advanced Digital Modeling

RepMold uses powerful 3D modeling software to build highly detailed mold designs. These models are optimized for maximum precision and manufacturability.

AI-Driven Geometry Optimization

Artificial intelligence evaluates designs, enhances structural strength, and removes unnecessary design elements, making the final mold efficient and durable.

High-Performance Material Forming

RepMold combines intelligent heat management and automated forming techniques to produce strong, high-quality molds with consistent output every time.

Automated Quality Inspection Systems

Every mold is automatically scanned and inspected using real-time monitoring systems, ensuring flawless accuracy before it even leaves the machine.

Advantages of RepMold Over Traditional Methods

Cost Savings

Less manual labor, fewer iterations, and reduced waste lead to significant cost reductions.

Faster Prototyping

Manufacturers can test ideas quickly, accelerating innovation and reducing risks.

Improved Product Consistency

Automation eliminates the inconsistencies that often occur with manual manufacturing.

Environmental Sustainability

RepMold uses energy-efficient systems and reduces material waste, making it an eco-friendly solution for the future.

Applications of RepMold Technology

Automotive Industry

RepMold supports the production of precision exterior and interior components, improving vehicle performance and aesthetics.

Aerospace Sector

With its high precision and lightweight tooling capabilities, RepMold meets the demanding needs of aerospace engineering.

Consumer Electronics

From smartphone casings to tiny circuit components, RepMold ensures flawless manufacturing for compact, high-tech devices.

Medical & Healthcare Devices

RepMold is ideal for producing sterilizable, high-precision medical instruments and disposable items.

Packaging Industry

It delivers fast and flexible mold production for packaging manufacturers looking to keep up with rapidly changing trends.

Case Studies & Real-World Success

Increased Efficiency in Automotive Components

Several automotive companies have reported reduced mold development time by up to 70% using RepMold’s, allowing them to release new parts faster.

High-Precision Medical Tooling

Medical manufacturers have achieved unprecedented accuracy in surgical tools, making procedures safer and more reliable.

Future of Mold Production with RepMold’s

Integration with Industry 4.0

RepMold’s is aligned with smart manufacturing trends, allowing seamless integration with IoT devices, smart factories, and real-time data systems.

AI and Automation Advancements

As AI evolves, RepMold’s will become even smarter—predicting issues before they occur and continuously improving mold quality.

Conclusion

RepMold’s is more than just a new technology—it’s a major leap forward for the entire manufacturing world. Its ability to deliver unmatched precision, blazing speed, and exceptional flexibility makes it a game-changer. As industries embrace automation and smart production systems, RepMold’s will continue to lead the way, shaping the future of mold-making with innovation and efficiency.