Introduction

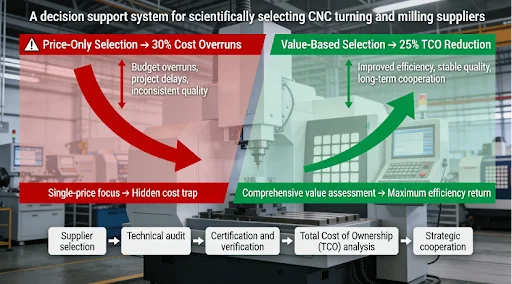

In today’s competitive manufacturing landscape, businesses frequently face costly inefficiencies — such as project delays, budget overruns, and quality inconsistencies — when selecting CNC turning and milling services providers. Many decision-makers rely solely on price comparisons, overlooking critical factors like technical capabilities, certifications, and long-term value. This approach often leads to mismatched supplier partnerships, especially for complex, high-precision components.

The root cause lies in the absence of a systematic evaluation framework that integrates technical, operational, and quality benchmarks. This guide provides a science-based methodology to help engineers, procurement specialists, and product managers avoid common pitfalls, optimize costs, and build a resilient supply chain. By focusing on key metrics — from equipment compatibility to certification rigor — readers will learn to identify partners capable of driving innovation and efficiency.

What Are the Common Pitfalls in Selecting a CNC Turning and Milling Services Provider?

Many organizations fall into predictable traps when choosing a supplier, often due to incomplete or outdated evaluation criteria. Recognizing these pitfalls is the first step toward mitigation.

l Overemphasis on Unit Price Instead of Total Cost of Ownership: Focusing exclusively on per-part pricing ignores hidden expenses like rework, delays, and tooling adjustments. For example, a supplier with a 20% lower quote may lack multi-axis capabilities, necessitating additional setups and increasing total costs by 30% or more. A total cost of ownership (TCO) analysis — factoring in lead times, defect rates, and logistics — provides a more accurate financial picture.

l Neglecting Equipment Compatibility and Technological Maturity: Not all CNC machinery suits every project. Suppliers using outdated 3-axis systems may struggle with complex geometries, leading to compromised tolerances or design alterations. Auditing a provider’s equipment — such as 5-axis CNC centers or turn-mill combinations — ensures alignment with technical requirements. Referencing standards like ASME Y14.5-2018 helps validate geometric tolerance capabilities.

l Underestimating the Role of Certifications in Risk Mitigation: Certifications like ISO 9001 are not mere badges; they signify adherence to rigorous quality management systems. A supplier without such credentials may exhibit inconsistent processes, increasing the risk of non-conformance. For regulated industries (e.g., aerospace or medical devices), certifications like AS9100D or ISO 13485 are non-negotiable for compliance and traceability.

How Can Combined Machining Solutions Drive Innovation and Effiiency?

Integrated turning and milling services, enabled by advanced turn-mill centers, eliminate traditional bottlenecks by consolidating operations into a single setup. This approach enhances precision while reducing timelines.

1. Single-Setup Machining: Reducing Handling and Errors

By performing turning, milling, and drilling in one cycle, combined machining minimizes workpiece handling and cumulative errors. A case study involving an aerospace valve body showed a 40% reduction in production time and a 25% improvement in concentricity tolerances compared to multi-stage processing.

2. Enabling Design Complexity and Lightweighting

Turn-mill systems support free-form surfaces and thin-walled structures that are infeasible with conventional methods. For instance, a drone component with internal cooling channels was produced in one piece, eliminating assembly joints and enhancing thermal performance. This aligns with Industry 4.0 principles of design consolidation and functional integration.

3. Streamlining Prototyping to Production Transitions

With unified programming and machining, combined solutions accelerate iterations. A medical device manufacturer reduced prototyping cycles from 6 weeks to 10 days by leveraging a supplier’s integrated CAD/CAM workflows, ensuring seamless scaling to mass production.

What Technical Criteria Should Define Your CNC Supplier Evaluation?

A rigorous technical assessment prevents overpromising and underdelivery. Key criteria span machinery, materials, and measurable performance benchmarks.

1. Multi-Axis Capability and Tolerance Assurance

Suppliers should demonstrate proficiency in 5-axis machining for tasks like contouring or deep-cavity drilling. Validate their ability to hold tolerances within ±0.005 mm through sample parts or process documentation. Equipment with real-time monitoring systems further ensures stability during long production runs.

2. Material Compatibility and Tooling Expertise

A provider’s experience with materials — from titanium alloys to engineering plastics — impacts outcomes. Inquire about tool-wear management strategies and coolant protocols for specific materials. For example, machining PEEK requires low thermal stress to prevent deformation, necessitating specialized toolpaths.

3. Certification as a Proxy for Process Rigor

Certifications like ISO 14001 (environmental management) signal operational maturity. A supplier’s IATF 16949 certification, for instance, underscores capability in automotive precision components, with documented controls for defect prevention.For integrated services, professional CNC turning and milling services ensure a seamless workflow.

How Do Quality Certifications Like ISO 9001 Impact Manufacturing Outcomes?

Beyond compliance, certifications institutionalize consistency, traceability, and continuous improvement. Their absence often correlates with higher failure rates.

1. Standardizing Processes and Reducing Variability: ISO 9001-certified suppliers implement standardized workflows for calibration, inspection, and documentation. This reduces deviation rates — e.g., maintaining defect rates below 0.5% — as verified through statistical process control (SPC) data.

2. Enhancing Traceability and Accountability: For regulated industries, certifications mandate full traceability from raw material to finished part. In one incident, a medical implant manufacturer used ISO 13485 protocols to trace a non-conformance to a specific batch of material, preventing a recall.

3. Facilitating Audits and Customer Confidence: Certified suppliers undergo regular third-party audits, providing clients with transparent access to performance data. This builds trust and simplifies supplier qualification processes, especially for global partnerships.

What Are the Hidden Costs in Combined Machining, and How to Optimize Them?

While integrated machining saves time, unaddressed hidden costs can erode savings. A proactive approach identifies and mitigates these risks.

1. Programming and Setup Expenses

Complex CNC programs require advanced CAM software and skilled engineers, adding upfront costs. However, modular tooling designs and standardized fixtures can reduce setup charges by 15–20% for repeat orders.

2. Tool Wear and Maintenance Burdens

Multi-axis machining accelerates tool wear due to continuous engagement. Suppliers with predictive maintenance systems can schedule replacements based on actual usage, cutting tool costs by 10% and avoiding unplanned downtime.

3. Logistics and Inventory Carrying Costs

Overseas suppliers may offer lower rates but incur higher logistics expenses. A regional supplier with turnkey solutions might provide better TCO through reduced shipping times and lower inventory buffers.

How Can Advanced Multi-Axis Machining Transform Complex Part Production?

The evolution from 3- to 5-axis machining represents a paradigm shift in precision, efficiency, and design freedom.

l Overcoming Geometric Constraints: 5-axis CNC machining enables simultaneous movement along linear and rotational axes, allowing tools to maintain optimal orientation to curved surfaces. This eliminates manual repositioning and ensures consistent surface finish on impellers or turbine blades.

l Shortening Cycles and Improving Resource Utilization: By combining operations, 5-axis systems cut idle time and tool changes. An automotive client reduced a mold component’s machining time from 18 to 11 hours, boosting equipment utilization rates by 35%.

l Enabling Digital Twin Integration: In smart factories, 5-axis machines act as data nodes, feeding real-time performance metrics into digital twins. This allows simulation-driven optimizations, such as adaptive feed rates, further reducing energy use and cycle times.

Conclusion

Selecting a CNC turning services provider demands a holistic strategy that balances technical prowess, certifications, and total cost. By prioritizing systematic evaluations over price-alone decisions, manufacturers can avoid costly errors, accelerate innovation, and build partnerships that drive long-term efficiency. As industries embrace digital transformation, partnering with technologically advanced, certified suppliers becomes indispensable for competitiveness.

FAQs

Q1: What is the minimum order quantity for combined CNC turning and milling services?

A: Most professional suppliers, including those with ISO 9001 certification, offer flexible MOQs from prototyping to mass production. This allows businesses to test quality without large commitments, typically with no minimum for initial samples to enable cost-effective validation.

Q2: How does CNC turning differ from milling in terms of application?

A: CNC turning rotates the workpiece against a stationary tool, ideal for cylindrical parts like shafts, while milling moves a rotating tool across a stationary workpiece for complex geometries. The choice depends on part design; combined services integrate both for efficiency, referencing ASME Y14.5 standards for tolerance guidelines.

Q3: What quality controls should I expect from a certified supplier?

A: Suppliers with ISO 9001 or AS9100D certification should provide in-process inspections, CMM reporting, and material traceability. For instance, leading providers employ statistical process control to maintain defect rates below 0.5%, ensuring compliance with industry benchmarks.

Q4: Can I modify an order after placement with a combined machining supplier?

A: Yes, reputable suppliers have change management systems to accommodate modifications, though timing may affect costs. It’s best to discuss flexibility during quoting to avoid delays, as integrated platforms often allow real-time updates.

Q5: How long does it typically take to receive parts from an overseas supplier?

A: Lead times vary but average 1-3 weeks for overseas shipments, including production and logistics. Suppliers with lean processes, such as those using multi-axis machining, can expedite to 5-7 days, so always confirm options during selection.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company dedicated to helping engineers and researchers overcome complex part challenges in aerospace, medical, and automotive sectors. With certifications including IATF 16949 and AS9100D, the team ensures high-quality solutions through advanced technologies. For further insights, contact them today for a free, no-obligation project review and DFM analysis.