Every enterprise prospers on innovation. In my years of working with electric and industrial materials, I’ve seen countless technologies come and cross. Yet, one procedure that continues to prove its well worth throughout more than one field is vacuum metallizing. What started as a manner to feature ornamental finishes has now turned out to be a powerful method for developing coatings which can be long lasting, green, and sustainable.

At Shieldingtape.Com, I’ve watched customers pass from experimenting with this technology to making it a trendy part of their manufacturing procedure. And the results were tremendous—merchandise that no longer best remains longer however also carry out with greater reliability in annoying environments.

Discover insights from similar posts that will deepen your understanding!

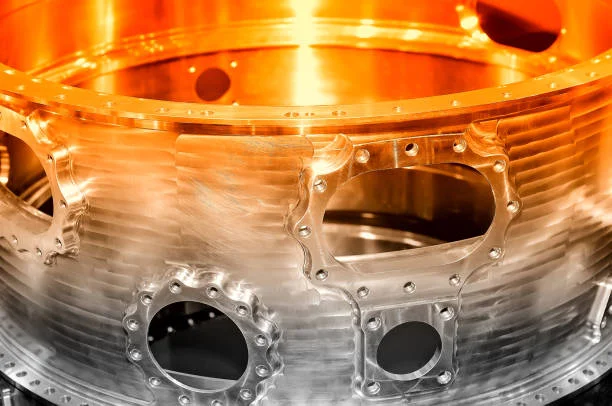

How Vacuum Metallizing Works

The concept at the back of vacuum metallizing is straightforward yet fairly effective. A base fabric—plastic, glass, or polyester film—is located inside a vacuum chamber. Metal, normally aluminum, is heated until it vaporizes after which condenses onto the floor, forming a skinny but robust layer.

Unlike paints or chemical coatings, vacuum metallization

produces a uniform finish that adheres tightly without peeling or cracking. It’s a manner that blends technological know-how with practicality, growing coatings that may serve each purposeful and decorative purposes.

What strikes me most about this process is its capacity to attain a lot with so little. A skinny coating of steel can alternate the whole performance of a product—enhancing reflectivity, enhancing insulation, or strengthening resistance to outside elements.

Real-World Applications That Matter

Over the years, I’ve seen vacuum metallizing utilized in endless industries. Its fee lies inside the truth that it adapts to exclusive wishes:

Automotive: Headlamp reflectors and trim additives take advantage of each the shine and resilience of metallized coatings.

Electronics: Metallized layers improve conductivity and provide defense from electromagnetic interference, which is essential in today’s related international.

Packaging: Thin metallized films act as limitations in opposition to mild, moisture, and oxygen—maintaining meals and touchy products fresher for longer.

Aerospace: Lightweight coatings play a position in lowering standard weight while retaining sturdiness, assisting enhance strength efficiency.

From Japan’s electronics area to international automotive production, I’ve seen this generation carried out in ways that save fees, enhance performance, and enlarge product lifespans.

The Importance of Metallized PET Film

Among the products I advise most customarily is metallized PET film. This film combines flexibility with strength and is extensively utilized in electrical, industrial, and packaging programs.

Here’s why it stands proud:

Electrical Insulation: Ideal for transformers, capacitors, and tapes wherein safety is important.

Heat Resistance: Performs well in excessive-temperature environments.

Barrier Protection: Keeps moisture and oxygen out, making it a fave inside the packaging industry.

Durability with Flexibility: Strong but light-weight, clean to integrate into quite a few products.

From my personal enjoyment, switching to metallized PET film frequently gives producers a major development in overall performance without drastically increasing prices.

Why I Trust Shieldingtape.Com

I frequently inform clients that choosing the proper provider is just as vital as deciding on the proper product. At Shieldingtape.Com, we don’t simply provide substances—we offer peace of mind.

We’ve constructed our recognition of experience, working with clients throughout automobile, electrical, and commercial sectors.

Our products meet worldwide standards, making sure they are constantly pleasant.

We emphasize trust and transparency, imparting assistance at every level—from selection to application.

Most importantly, we’re committed to innovation, retaining pace with the developing demands of cutting-edge industries.

Looking Toward the Future

What excites me about vacuum metallizing is that its ability is far from absolutely realized. With industries transferring in the direction of greener practices, this procedure gives an eco-friendly manner to reap overall performance without counting on harmful chemical substances.

When combined with advanced materials like metallized PET film, the possibilities multiply—better packaging, more potent electric insulation, and greater green designs for the entirety from patron items to aerospace technology.

Final Thoughts

The adventure from concept to introduction is constantly about finding smarter, greater green answers. Vacuum metallizing

is one of those rare innovations that bridges performance, sustainability, and price-effectiveness. Supported via substances like metallized PET film, it maintains its price in industries globally.

At Shieldingtape.Com, I’ve seen how the proper substances can turn a great concept into a long-lasting product. And as industries keep conforming, I consider vacuum metallizing to stay a cornerstone era that shapes the future of manufacturing.

Don’t miss out on our highlighted post—carefully selected for you!